ʻO ke kaʻina hana hana i hoʻololiʻia i nā'āpana pepa i hoʻololiʻia: Ke kaʻina hanaʻana, e hana ana, nā kaʻina hana hana.

1

2.ʻO ka hoʻomaʻemaʻeʻana: Ua hoʻokaʻawaleʻia ia i nā heluʻehāʻehā a, B,ʻo C a d, he kiʻekiʻe loa), a pēlā aku.

3.ʻO ka hanaʻana i nā mea waiwai: e hōʻoiaʻiʻoʻaʻole e hewa nā mea pono e pili ana i ka hana.

4

Ⅱ. Hānai.

Ma o ka mālama kamepiula kamepiula, ua kāohiʻia ka blanking e like me ka loli paona.

Pono:

1.

2. E hōʻemi i ka hōʻoleʻana o nā mea waiwai.

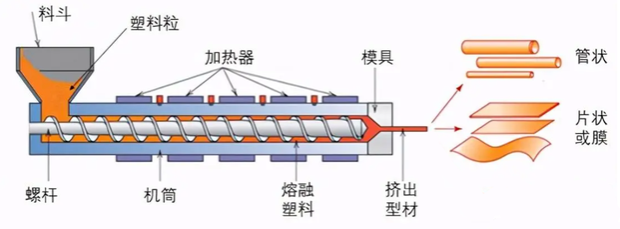

Ⅲ. Screw scarreizing, extrasion, kiʻi.

Ⅲ. Screw scarreizing, extrasion, kiʻi.

Ⅳ. Ka wai wai (sink).

Mālie aʻoluʻolu hoʻi i ke kaula plastik i hanaʻia mai ka mea i loaʻa mai.

Ⅴ. ʻO ka maloʻoʻana o ka ea

E wehe i ka mistature mai ka pale pepa a maloʻo ia.

Ⅵ. Kamula.

ʻO ka maʻamau,ʻo ka nui o nāʻokiʻoki i hōʻokiʻia he 3mm * 3mm PVC i ka maʻamau: GB / T8815-2002.

Ⅶ. Ke kauʻana (ka paleʻana i ke aniani).

Hoʻokiʻoki i nā'āpanaʻokiʻoki a kāohi i ka nui o nā'āpana.

Ⅷ. Overmagnezation (kānana kānana).

E hānai i nā'āpana me nā mea hao hao.

Ⅸ. Ke nānāʻana ma ka pūnaewele.

ʻO ia ka mea nui i keʻano o ka nānāʻana, eʻike ana inā he kala o nā'āpana o nā'āpana a hiki i keʻano maʻamau a inā he hanaʻia.

Ⅹ. Hui pūʻana (ʻelua cone rone rooner mix).

E hōʻoia e pili ana i ke kala a me ka hana o nā'āpana pepa i hoʻololiʻia.

Ⅺ. Hoʻopili i nā mīkini āpau-uila-uila a pau

Ⅻ. Huanui

POST manawa: 23-12-22