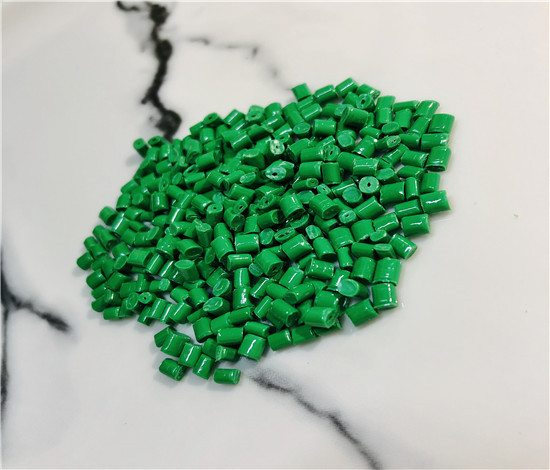

Pi (pulyimide) popder, cus, coup, Cn Deving huahana CCC

ʻIkeʻia nā polymoseting Posmoset e pili ana i ke kūpaʻaʻana, nā pale kaulike maikaʻi, maikaʻi loa, a me keʻano meleʻulaʻula /ʻulaʻula. Ua hoʻopiliʻia nā polyamides me nā kiʻi kiʻi kiʻi a iʻole nā mea i hoʻopaʻaʻia a iʻole nā mea i hoʻopaʻaʻia i ka 340 mpa (49,000,000 PPI). Ua hōʻikeʻo Poly i nā kiʻi paʻi Polymer Matrite Polyam Mālamaʻia kēia mau waiwai i ka wā e hoʻohana mau ana i nā mahana o ka 232 ° C (kiʻekiʻe e like me 704 ° F (1,299 ° F (1,299 ° F (1,299 ° F (1,299 ° F (1,299 ° F (1,299 ° F (1,299 ° F). ʻO nā'āpana polyded a me nā papa i hala a me nā heleʻana i nā pale wela maikaʻi. Nā hana maʻamau maʻamau no nā'āpana a me nā laminates i nā pae mai cryogenic i kēlā me kēia ma mua o 260 ° C (500 ° F). ʻO Poyamides ke kūʻole nei i ka paleʻana i ka lapalapa aʻaʻole pono e hoʻohuiʻia me nā mea kūʻai aku flame. Ka hapa nui o ka helu UL o VTM-0. Ua loaʻa iā Pymimide Laminate i kahi ikaika ikaika o ke ola ma 249 ° C (480 ° F (480 ° F) o 400 mau hola.

ʻAʻole i piliʻia nā'āpana polyitide e nā mea maʻamau i hoʻohana pinepineʻia a me nā aila - me nā hydrocarbons, nā mea he nui, a me nā ferns. Ua pale lākou i nā maʻi palupalu akāʻaʻole ia i kauohaʻia no ka hoʻohanaʻana i nāʻenehana i loaʻa i nā maʻi alkalis a iʻole nā aganicic a iʻole. ʻO kekahi mau polyamides, e like me cp1 a me nā corin xls, he selevent-slavent Hāʻawi nā waiwai kūpono i nā mea e pili ana iā lākou e pili ana i nā noi.

Nā Pāʻaniʻo Photos

Piʻo Piʻo ia ihoʻo Flame Retadant Poolmer,ʻaʻole ia e puhi i ka mahana kiʻekiʻe

ʻO nā mea mechanical properties haʻahaʻa haʻahaʻa i ka mahana

Loaʻa i ka waiwai ke kala i ke kala maikaʻi loa, hiki ke hoʻokō i nā koi likeʻole o ke kala kala

Hana maikaʻi maikaʻi loa: kiʻekiʻe kiʻekiʻe a me keʻano haʻahaʻa haʻahaʻa

ʻO ka hana uila uila:ʻO ka hoʻomaʻamaʻa uila uila

PI PAIA MAUI

Ua hoʻohana nuiʻia ma ka mīkini, nā mea hana, nā'āpana kaʻa, nā huahana hoʻonaninani, nā mea hana leʻaleʻa, nā hale hana nani, nā hale hana nani, nā hale hana nani, nā hale hana nani, nā hale hana nani, nā hale hana nani, nā hale hana maikaʻi.

ʻO Polyimide nā mea māmā,ʻo ka māmā, ke kūleʻa, ke kū'ēʻana i ka wela a me nā mea kanu. No laila, hoʻohanaʻia lākou i nāʻoihana uila no nā cerles a me keʻano o ka hoʻopiliʻana i nā kiʻi ma magnet. ʻO kahi hiʻohiʻona, i kahi kamepiula kamepiula, ka cable e hoʻopili ai i ka papa loiloi nui i weheʻia a paniʻia paha ke kumu kūʻai. ʻO nā hiʻohiʻona o nā kiʻiʻoniʻoni e komo i ka opical, kapton, pilalex, vtec pi, teron th a merrex.

ʻO kahi hoʻohana hou aku i ka resin resin e like me ka mea e hoʻohālikelike ai a me ka hōʻailonaʻana i ka papa hana i ka hana o nā hui hoʻohui a me nā pahu pahu. Loaʻa i nā papa polymideleloʻo PlyImide me ka ikaika a me ka ikaika o keʻano, e kōkua ana i ka ahulau ma waena o nā papa politika a iʻole ma waena o ka pālolo polyitide

| Kahua | Nā hihia noi |

| Kūʻai'āpana | ʻO ke kiʻekiʻe kiʻekiʻe e lawe nei i ka laweʻana i ka laweʻana, nā mea paʻi piston |

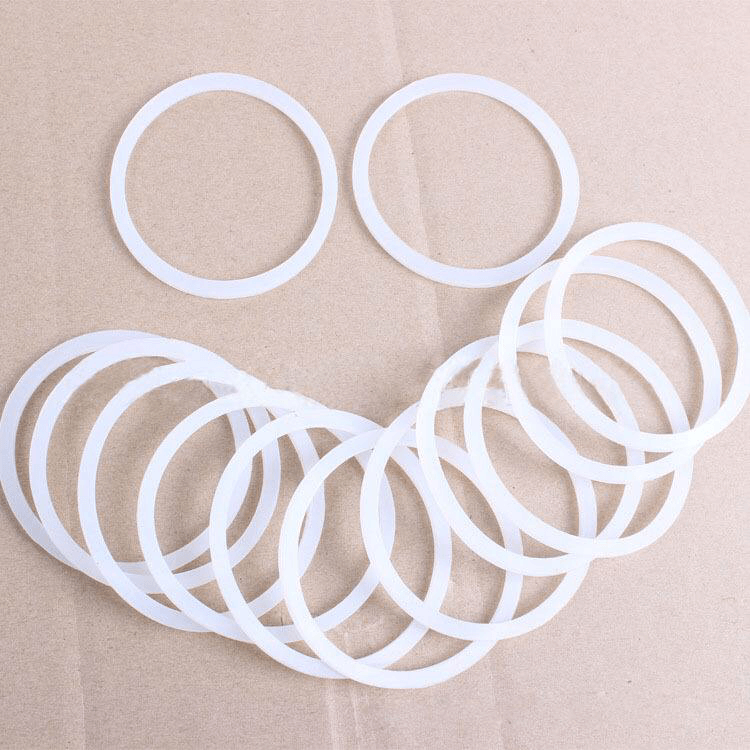

| Nā Pono Pono | Radiators, Mākaʻikaʻi Fanling, ke kūʻanaʻo Dank, Pihi Tank, Aquation Grisle, Ke Kahu Wai Pōhaku |

ʻO Spla-3D Budding a me ka wehewehe

| Kumu | ʻO ka weheweheʻana |

| Spla-3D101 | Papa kiʻekiʻe. Nā moʻolelo Pig no ka 90%. Ka hopena paʻi maikaʻi a me ka ikaika o ka hana. ʻO nā mea pono e kū pono ana i ka hanaʻana, e paʻi ana i nā mea paʻi kiʻi a me nā waiwai maikaʻi loa. |

| Spla-3DC102 | Nā moʻokāki Pig no 50-70% a ua piha loa a nui loa. ʻO nā pono kūpono e hana ana i ka hanaʻana, e nānā pono ana i nā waiwai mexcellent. |